Solving Power Quality Issues with Dry Core Transformers: A Comprehensive Guide

Solving Power Quality Issues with Dry Core Transformers

Table of Contents

Understanding Power Quality Issues

Introduction to Dry Core Transformers

Benefits of Dry Core Transformers

How Dry Core Transformers Improve Power Quality

Applications of Dry Core Transformers

Technical Specifications and Standards

Installation and Maintenance of Dry Core Transformers

Future

Solving Power Quality Issues with Dry Core Transformers

Table of Contents

- Understanding Power Quality Issues

- Introduction to Dry Core Transformers

- Benefits of Dry Core Transformers

- How Dry Core Transformers Improve Power Quality

- Applications of Dry Core Transformers

- Technical Specifications and Standards

- Installation and Maintenance of Dry Core Transformers

- Future Trends in Power Quality Management

- Frequently Asked Questions

- Conclusion

Understanding Power Quality Issues

Power quality issues are a significant concern for industries and commercial establishments. Fluctuations in voltage, frequency, or current can lead to equipment malfunction, energy wastage, and increased operational costs. Common power quality problems include voltage sags, swells, transients, and harmonic distortions. Understanding these issues is crucial for mitigating their impact on electrical systems.

Voltage sags, for instance, occur when the voltage drops below the normal level for a brief period. This can happen due to sudden changes in load or faults in the power distribution system. Conversely, voltage swells represent temporary increases in voltage, which can cause serious damage to sensitive electronic equipment. Additionally, harmonic distortion arises from non-linear loads and can interfere with the performance of electrical devices.

By addressing these power quality issues, industries can enhance equipment lifespan, reduce maintenance costs, and ensure a more reliable power supply.

Introduction to Dry Core Transformers

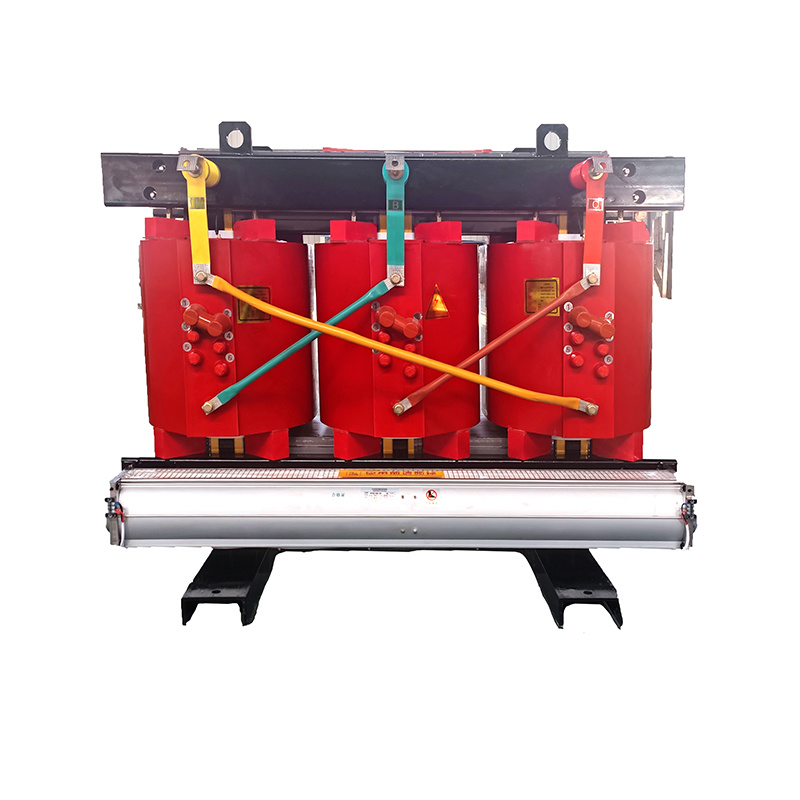

Dry core transformers are a type of transformer that utilizes air as a cooling medium instead of liquid insulation. They are designed to operate efficiently in various environmental conditions, making them ideal for applications where moisture and contamination are concerns. The core is made from high-grade silicon steel sheets, which are insulated to minimize eddy current losses.

These transformers provide several advantages over traditional oil-filled transformers, especially in terms of maintenance and safety. As they do not contain flammable liquids, dry core transformers pose a lower risk of fire and environmental contamination. Their compact design also allows for easier installation and integration into existing electrical systems.

Benefits of Dry Core Transformers

Dry core transformers offer numerous benefits that contribute to solving power quality issues:

1. Enhanced Safety

Without liquid insulation, dry core transformers eliminate the risk of leaks and fires, making them a safer choice for many applications.

2. Low Maintenance Requirements

These transformers require less maintenance compared to their oil-filled counterparts. The absence of oil reduces the need for regular inspections and potential environmental cleanups.

3. Improved Efficiency

Dry core transformers exhibit high efficiency levels, minimizing energy losses during operation. This efficiency translates to lower operational costs and improved overall power quality.

4. Compact Design

Their smaller footprint allows for easier installation in confined spaces, making them suitable for various environments, including urban settings.

5. Environmentally Friendly

As they do not use oil, these transformers are more environmentally friendly, contributing to sustainable practices in power management.

How Dry Core Transformers Improve Power Quality

Dry core transformers play a crucial role in enhancing power quality by addressing several key issues:

1. Voltage Regulation

By stabilizing voltage levels, dry core transformers minimize the risk of voltage sags and swells. This regulation ensures that sensitive equipment operates within safe voltage ranges, thereby preventing damage.

2. Reduced Harmonic Distortion

These transformers can be designed to filter out harmonics, improving the overall power quality and reducing the potential impact on connected devices.

3. Isolation of Sensitive Equipment

Dry core transformers provide electrical isolation, protecting sensitive equipment from fluctuations in the power supply. This isolation helps in maintaining consistent performance levels.

4. Load Balancing

By distributing electrical loads evenly, dry core transformers can help mitigate issues related to unbalanced phases, further enhancing power quality.

Applications of Dry Core Transformers

Dry core transformers are versatile and can be utilized in various sectors:

1. Industrial Applications

Manufacturing and processing industries often face power quality challenges. Dry core transformers can help ensure stable power supply for machinery and equipment.

2. Commercial Buildings

In commercial establishments, these transformers provide reliable power for lighting, HVAC systems, and other essential services.

3. Renewable Energy Systems

With the rise of renewable energy sources, dry core transformers are increasingly used in solar and wind energy systems to manage power output and quality.

4. Data Centers

Data centers rely heavily on stable power supply. Dry core transformers can mitigate power quality issues, ensuring uninterrupted operations.

5. Transportation Systems

Dry core transformers are essential in railways and other transportation systems, providing reliable power for signaling and operational systems.

Technical Specifications and Standards

When considering dry core transformers, it is essential to understand their technical specifications and the standards that govern their design and operation.

1. Efficiency Ratings

Efficiency ratings, such as the National Electrical Manufacturers Association (NEMA) standards, indicate the transformer's energy efficiency. Choosing a transformer with high efficiency can lead to significant energy savings.

2. Voltage Ratings

Dry core transformers come in various voltage ratings to accommodate different applications. Selecting the right voltage rating is crucial for optimal performance.

3. Noise Levels

Noise emissions from transformers can impact nearby environments. Dry core transformers are designed to minimize noise levels, making them suitable for urban and residential areas.

4. Environmental Standards

Compliance with environmental standards, such as ISO 14001, ensures that the transformers meet necessary regulations for environmental protection.

Installation and Maintenance of Dry Core Transformers

Proper installation and maintenance are vital for maximizing the benefits of dry core transformers.

1. Installation Guidelines

Installation should be carried out by qualified personnel. Factors such as location, ventilation, and accessibility must be considered to ensure optimal performance.

2. Routine Maintenance

Routine inspections and maintenance are essential to identify potential issues before they escalate. Regular checks on connections, insulation, and overall condition can prolong the transformer’s lifespan.

3. Troubleshooting Common Issues

Understanding common issues, such as overheating or unusual noise, helps in quick troubleshooting. Addressing these issues promptly can prevent costly downtime.

Future Trends in Power Quality Management

As industries continue to evolve, the demand for improved power quality management solutions is growing. Dry core transformers are positioned to play a significant role in this landscape:

1. Smart Grid Technology

Integration with smart grid technology can enhance the monitoring and management of power quality, allowing for real-time data analysis and adjustments.

2. Increased Focus on Sustainability

With a growing emphasis on sustainability, dry core transformers will likely see increased adoption as they align with eco-friendly practices.

3. Advancements in Technology

Technological advancements will continue to improve the performance and efficiency of dry core transformers, making them even more effective in addressing power quality issues.

Frequently Asked Questions

1. What are dry core transformers?

Dry core transformers are transformers that use air for cooling instead of oil. They are designed for various applications and are known for their safety and low maintenance.

2. How do dry core transformers improve power quality?

They stabilize voltage levels, reduce harmonic distortion, isolate sensitive equipment, and enhance load balancing, leading to improved overall power quality.

3. Where are dry core transformers commonly used?

They are used in industrial applications, commercial buildings, renewable energy systems, data centers, and transportation systems.

4. What are the maintenance requirements for dry core transformers?

They require routine inspections and maintenance to ensure optimal performance, focusing on connections, insulation, and overall condition.

5. Are dry core transformers environmentally friendly?

Yes, they do not contain oil, making them a more environmentally friendly option compared to traditional oil-filled transformers.

Conclusion

In summary, **dry core transformers** present an effective solution for addressing power quality issues across different industries. Their ability to enhance safety, reduce maintenance needs, and improve efficiency positions them as a preferred choice for modern electrical systems. As we move towards a future focused on sustainability and advanced technology, the role of dry core transformers will only become more prominent in ensuring reliable and high-quality power supply. Investing in these transformers can significantly benefit various applications, leading to enhanced operational efficiency and reduced costs.

Key words:

Recommended

Why a Dry Distribution Transformer is Essential for Modern Electrical Systems

Why a Dry Distribution Transformer is Essential for Modern Electrical Systems

Table of Contents

1. Introduction to Dry Distribution Transformers

2. What is a Dry Distribution Transformer?

3. Advantages of Dry Distribution Transformers

3.1 Enhanced Safety Features

3.2 Energy Efficiency and Environmental Impact

3.3 Reduced M