Why a Dry Distribution Transformer is Essential for Modern Electrical Systems

Why a Dry Distribution Transformer is Essential for Modern Electrical Systems

Table of Contents

1. Introduction to Dry Distribution Transformers

2. What is a Dry Distribution Transformer?

3. Advantages of Dry Distribution Transformers

3.1 Enhanced Safety Features

3.2 Energy Efficiency and Environmental Impact

3.3 Reduced M

Why a Dry Distribution Transformer is Essential for Modern Electrical Systems

Table of Contents

- 1. Introduction to Dry Distribution Transformers

- 2. What is a Dry Distribution Transformer?

- 3. Advantages of Dry Distribution Transformers

- 3.1 Enhanced Safety Features

- 3.2 Energy Efficiency and Environmental Impact

- 3.3 Reduced Maintenance Requirements

- 4. Applications of Dry Distribution Transformers

- 5. Comparison with Oil-Filled Transformers

- 6. Installation and Usage Tips for Dry Distribution Transformers

- 7. Future Trends in Transformer Technology

- 8. Frequently Asked Questions

- 9. Conclusion

1. Introduction to Dry Distribution Transformers

In the evolving landscape of electrical systems, **dry distribution transformers** have emerged as a cornerstone for efficient and safe power management. With a focus on innovation and sustainability, these transformers are increasingly recognized for their significant advantages in various industrial, commercial, and residential applications. Understanding their vital role can help stakeholders make informed decisions regarding electrical infrastructure.

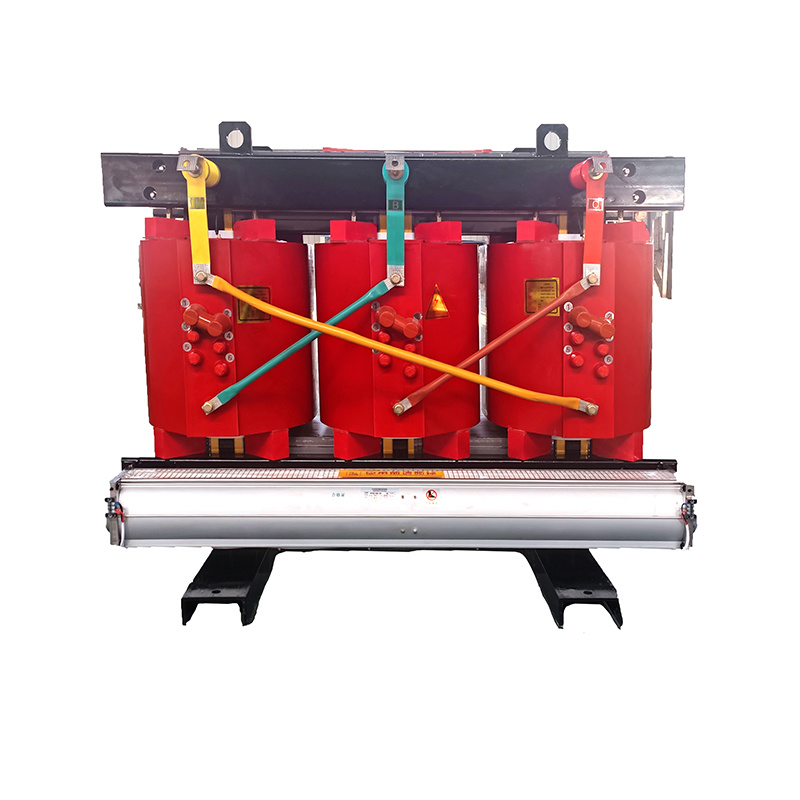

2. What is a Dry Distribution Transformer?

A **dry distribution transformer**, unlike its oil-filled counterparts, utilizes air cooling and solid insulation to operate effectively. They are designed to convert voltage levels in electrical systems while ensuring minimal energy loss and enhanced safety. These transformers are typically constructed with materials that can withstand high temperatures and are suitable for environments where flammable liquids are not desirable.

3. Advantages of Dry Distribution Transformers

The preference for dry transformers stems from several inherent advantages that cater to modern electrical demands.

3.1 Enhanced Safety Features

Safety is paramount in electrical systems. Dry distribution transformers eliminate the risk of oil leaks and fire hazards associated with oil-filled transformers. They are particularly advantageous in urban areas and facilities where fire codes are stringent. The use of non-flammable materials enhances the overall safety profile of electrical installations, making them an ideal choice for schools, hospitals, and commercial buildings.

3.2 Energy Efficiency and Environmental Impact

Dry transformers are designed for high energy efficiency. The solid insulation and air-cooling mechanisms significantly reduce energy losses, contributing to lower operational costs. Furthermore, the absence of hazardous fluids makes them an environmentally friendly option, aligning with the growing emphasis on sustainable practices in the electrical industry.

3.3 Reduced Maintenance Requirements

One of the standout features of dry distribution transformers is their minimal maintenance needs. Without the complexities of oil management and potential leaks, operators can enjoy reduced downtime and lower maintenance costs. Many manufacturers offer long warranty periods, further underscoring the reliability of these transformers.

4. Applications of Dry Distribution Transformers

Dry distribution transformers find applications across various sectors due to their versatile nature. Some of the key areas where they are utilized include:

- **Commercial Buildings**: Offices, shopping malls, and hotels benefit from reliable power distribution without the risk of oil leaks.

- **Industrial Facilities**: Factories and manufacturing plants, particularly those with stringent safety codes, prefer dry transformers for their robust performance.

- **Renewable Energy Systems**: As the world shifts towards renewable energy, dry transformers play a pivotal role in wind and solar installations.

- **Data Centers**: The need for consistent, reliable power makes dry transformers an integral part of data center infrastructure.

5. Comparison with Oil-Filled Transformers

When evaluating the choice between dry and oil-filled transformers, several factors come into play.

- **Cooling Mechanisms**: Oil-filled transformers utilize oil for cooling, while dry transformers rely on air. This distinction affects the installation environment and safety considerations.

- **Environmental Concerns**: Oil-filled transformers pose environmental risks due to potential leaks. In contrast, dry transformers are free from hazardous substances, making them more suitable for eco-conscious projects.

- **Cost Considerations**: Although the initial investment for oil-filled transformers may be lower, the long-term costs associated with maintenance and environmental compliance can outweigh these savings.

6. Installation and Usage Tips for Dry Distribution Transformers

Proper installation and usage are crucial for maximizing the benefits of dry distribution transformers. Here are essential tips to consider:

- **Site Selection**: Choose an installation site with adequate space for ventilation. Proper airflow is essential for cooling.

- **Regular Inspections**: While maintenance is minimal, regular inspections can help identify issues before they become significant problems.

- **Load Management**: Ensure the transformer is appropriately sized for the load it will handle to avoid overheating and inefficiencies.

7. Future Trends in Transformer Technology

The transformer industry is on the brink of technological advancements that will further enhance the performance and application of dry distribution transformers. Key trends include:

- **Smart Transformer Technology**: Integration of IoT devices for monitoring performance and predictive maintenance.

- **Sustainability Initiatives**: Enhanced focus on eco-friendly materials and energy-efficient designs in transformer manufacturing.

- **Modular Designs**: The development of modular transformers that allow for easier installation and scalability in growing electrical systems.

8. Frequently Asked Questions

1. What is the lifespan of a dry distribution transformer?

The lifespan of a dry distribution transformer typically ranges from 25 to 40 years, depending on usage and maintenance practices.

2. Are dry transformers more expensive than oil-filled transformers?

While the initial purchase price of dry transformers may be higher, their lower maintenance costs and enhanced safety features often make them more economical in the long run.

3. Can dry distribution transformers be used outdoors?

Yes, dry transformers can be used outdoors if they are properly housed and protected from environmental elements.

4. Do dry transformers require special installation considerations?

Yes, proper ventilation and sufficient space for cooling are essential for the effective installation of dry transformers.

5. What are the most common sizes for dry distribution transformers?

Dry distribution transformers typically range from 15 kVA to 5000 kVA, catering to various application needs.

9. Conclusion

In conclusion, dry distribution transformers are indispensable components of modern electrical systems, offering numerous advantages over traditional oil-filled units. Their superior safety features, energy efficiency, and reduced maintenance requirements make them the preferred choice for a wide range of applications. As technology continues to evolve, dry transformers will undoubtedly play a pivotal role in shaping the future of electrical distribution, meeting the demands of sustainability and safety in our increasingly electrified world. Embracing this technology not only enhances operational efficiency but also aligns with global efforts toward greener energy solutions.

Key words:

Recommended

Why a Dry Distribution Transformer is Essential for Modern Electrical Systems

Why a Dry Distribution Transformer is Essential for Modern Electrical Systems

Table of Contents

1. Introduction to Dry Distribution Transformers

2. What is a Dry Distribution Transformer?

3. Advantages of Dry Distribution Transformers

3.1 Enhanced Safety Features

3.2 Energy Efficiency and Environmental Impact

3.3 Reduced M