Understanding Dry Core Transformers: A Comprehensive Overview

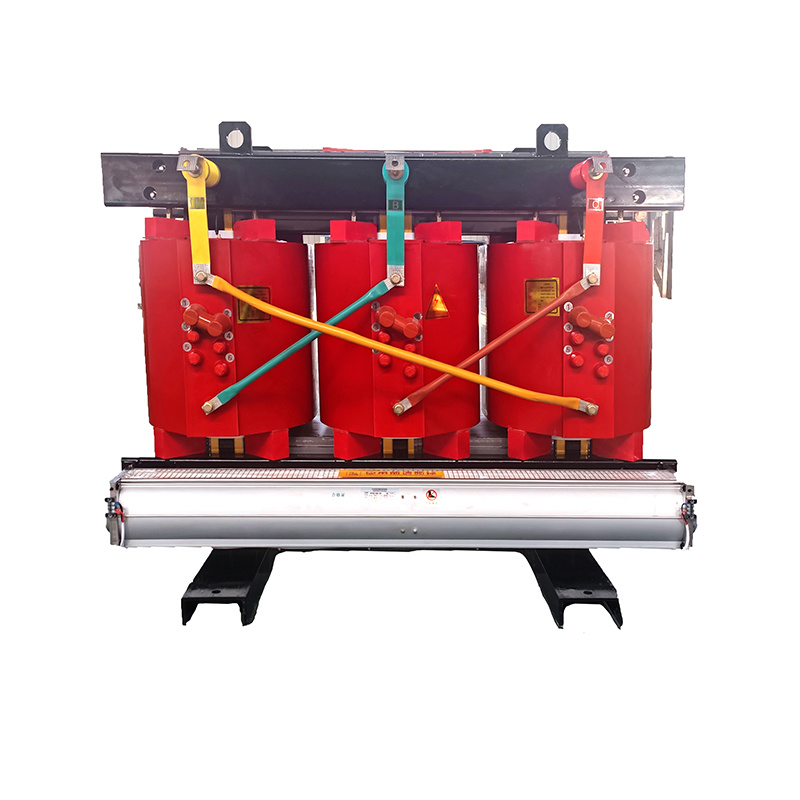

Dry core transformers are a crucial component in the electrical and power distribution systems, known for their unique construction and operational advantages. Unlike traditional liquid-filled transformers, dry core transformers utilize air as the primary cooling medium, which significantly influences their design and functionality.

One of the standout features of dry core transformers is their in

Dry core transformers are a crucial component in the electrical and power distribution systems, known for their unique construction and operational advantages. Unlike traditional liquid-filled transformers, dry core transformers utilize air as the primary cooling medium, which significantly influences their design and functionality.

One of the standout features of dry core transformers is their insulation method. These transformers typically employ solid insulation materials, such as epoxy resin or other thermosetting substances, to encapsulate their windings and core. This design eliminates the risk of oil leaks, which can be a significant safety hazard in environments where flammable materials are present. Thus, these transformers are often favored in indoor installations and locations requiring high safety standards.

The operational benefits of dry core transformers extend beyond safety. They exhibit excellent thermal performance due to their reduced weight and size, making them easier to install and maintain compared to their liquid-filled counterparts. Additionally, dry core transformers are less susceptible to environmental conditions, such as humidity and temperature fluctuations. This resilience translates into a longer lifespan and reduced maintenance requirements, ultimately leading to lower operational costs.

Dry core transformers find a wide range of applications across various sectors. They are commonly utilized in building power systems, industrial facilities, and renewable energy installations, such as wind and solar farms. Their compact design and efficient operation make them ideal for situations where space is limited and reliability is paramount.

When it comes to maintenance, dry core transformers are generally easier to service because of their accessible design. Regular inspections should focus on the condition of the insulation, the cleanliness of the core and windings, and overall physical integrity. Keeping these components in optimal condition is essential for ensuring reliable performance and extending the operational life of the transformer.

In summary, dry core transformers are a versatile and reliable option for power distribution needs. Their unique construction provides significant advantages in terms of safety, efficiency, and maintenance. By choosing dry core transformers, professionals can ensure a safer and more efficient electrical infrastructure, capable of meeting the demands of various applications while minimizing environmental impact. Whether you're considering a new installation or evaluating existing equipment, understanding the merits of dry core transformers is essential in the modern landscape of electrical engineering.

One of the standout features of dry core transformers is their insulation method. These transformers typically employ solid insulation materials, such as epoxy resin or other thermosetting substances, to encapsulate their windings and core. This design eliminates the risk of oil leaks, which can be a significant safety hazard in environments where flammable materials are present. Thus, these transformers are often favored in indoor installations and locations requiring high safety standards.

The operational benefits of dry core transformers extend beyond safety. They exhibit excellent thermal performance due to their reduced weight and size, making them easier to install and maintain compared to their liquid-filled counterparts. Additionally, dry core transformers are less susceptible to environmental conditions, such as humidity and temperature fluctuations. This resilience translates into a longer lifespan and reduced maintenance requirements, ultimately leading to lower operational costs.

Dry core transformers find a wide range of applications across various sectors. They are commonly utilized in building power systems, industrial facilities, and renewable energy installations, such as wind and solar farms. Their compact design and efficient operation make them ideal for situations where space is limited and reliability is paramount.

When it comes to maintenance, dry core transformers are generally easier to service because of their accessible design. Regular inspections should focus on the condition of the insulation, the cleanliness of the core and windings, and overall physical integrity. Keeping these components in optimal condition is essential for ensuring reliable performance and extending the operational life of the transformer.

In summary, dry core transformers are a versatile and reliable option for power distribution needs. Their unique construction provides significant advantages in terms of safety, efficiency, and maintenance. By choosing dry core transformers, professionals can ensure a safer and more efficient electrical infrastructure, capable of meeting the demands of various applications while minimizing environmental impact. Whether you're considering a new installation or evaluating existing equipment, understanding the merits of dry core transformers is essential in the modern landscape of electrical engineering.

Key words:

Recommended

Why a Dry Distribution Transformer is Essential for Modern Electrical Systems

Why a Dry Distribution Transformer is Essential for Modern Electrical Systems

Table of Contents

1. Introduction to Dry Distribution Transformers

2. What is a Dry Distribution Transformer?

3. Advantages of Dry Distribution Transformers

3.1 Enhanced Safety Features

3.2 Energy Efficiency and Environmental Impact

3.3 Reduced M