Basic working principle and structure of transformer

A transformer is a device that uses the principle of electromagnetic induction to change the alternating current voltage, and the main components are the primary coil, the secondary coil and the iron core (magnetic core). The main functions are: voltage conversion, current conversion, impedance conversion, isolation, voltage stabilization (magnetic saturation transformer), etc.

Transformers can be divided into distribution transformers, power transformers, fully sealed transformers, combined transformers, dry-type transformers, oil-immersed transformers, single-phase transformers, electric furnace transformers, rectifier transformers, reactors, anti-interference transformers, lightning protection transformers, box-type transformer test transformers, corner transformers, high-current transformers, excitation transformers, etc.

Transformer is the basic equipment for power transmission and distribution, which is widely used in industry, agriculture, transportation, urban communities and other fields. There are about 17 million transformers in operation in China, with a total capacity of about 11 billion kVA. The transformer loss accounts for about 40% of the power loss of transmission and distribution, and has great potential for energy saving.

A transformer is a device that uses the principle of electromagnetic induction to change the alternating voltage, and the main components are the primary coil, the secondary coil and the core (core). In electrical equipment and wireless circuits, it is often used as voltage lifting, impedance matching, safety isolation, etc. In generators, electric potential can be induced in the coil, regardless of whether the coil motion passes through a magnetic field or the magnetic field moves through a fixed coil. In both cases, the value of the magnetic flux does not change, but the amount of magnetic flux that intersects the coil changes, which is the principle of mutual induction. A transformer is a device that uses electromagnetic mutual induction to transform voltage, current, and impedance.

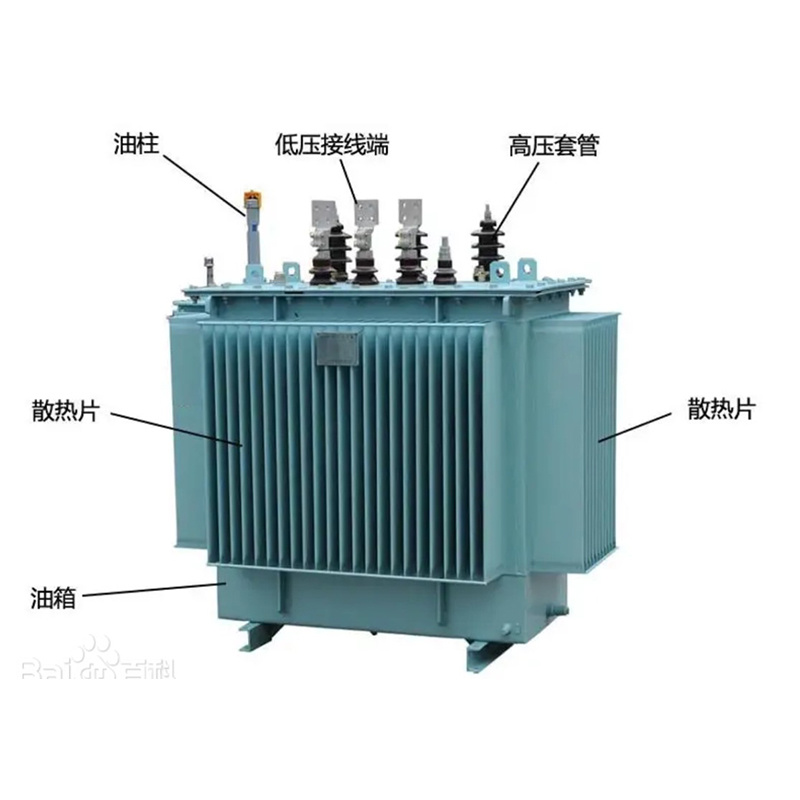

The transformer components include the body (core, winding, insulation, lead), transformer oil, oil tank and cooling device, voltage regulating device, protection device (dehydrating absorber, safety air channel, gas relay, oil conservator and temperature measuring device, etc.) and outlet bushing. Specific composition and function:

(1) Iron core. The iron core is the main part of the magnetic circuit in a transformer. Generally, the silicon content is high, the thickness is 0.35mm, 0.3mm, 0.27mm, and the surface is coated with insulating paint hot-rolled or cold-rolled silicon steel sheets stacked. The iron core is divided into two parts: the iron core column and the transverse piece, and the iron core column is sleeved with winding; The transverse plate is used to close the magnetic circuit.

(2) Winding. The winding is the circuit part of the transformer, which is wound with double wire coated insulated flat wire or enameled round wire. The basic principle of the transformer is the principle of electromagnetic induction, and now the single-phase double-winding transformer is taken as an example to illustrate its basic working principle: when the voltage U1 is added to the primary side winding, the current I1 flows through, and the alternating magnetic flux O1 is generated in the iron core, and these magnetic fluxes are called the main magnetic flux, under its action, the windings on both sides induce the electric potential respectively, and finally drive the transformer control device.

1. The classification standard of transformer 1, according to the voltage level, can be divided into: 1000KV, 750KV, 500KV, 330KV, 220KV, 110KV, 66KV, 35KV, 20KV, 10KV, 6KV, 0.66KV, 0.38KV, 0.22KV, etc. 2. According to the insulation and heat dissipation medium: dry-type transformer, oil-immersed transformer, of which dry-type transformer is divided into: SCB epoxy resin cast dry-type transformer and SGB10 non-encapsulated H-class insulated dry-type transformer.

3. According to the core structure material: silicon steel laminated transformer, silicon steel coiled core transformer, amorphous alloy core transformer.

4. According to the design energy-saving sequence: SG, SJ, S7, S9, S11, S13, S15.

5. According to the number of phases: single-phase transformer, three-phase transformer.

6. According to capacity: the rated capacity of transformers in China is 3KVA, 5KVA, 10KVA, 15KVA, 20KVA, 25KVA, 30KVA, 40KVA, 50KVA, 80KVA, 100KVA, 125KVA, 160KVA, 200KVA, 250KVA, 315KVA, 400KVA, 500KVA, 630KVA, 800KVA, 1000KVA, 1250KVA, 1600KVA, 2000KVA, 2500KVA, 3150KVA, 4000KVA, 5000KVA, etc.

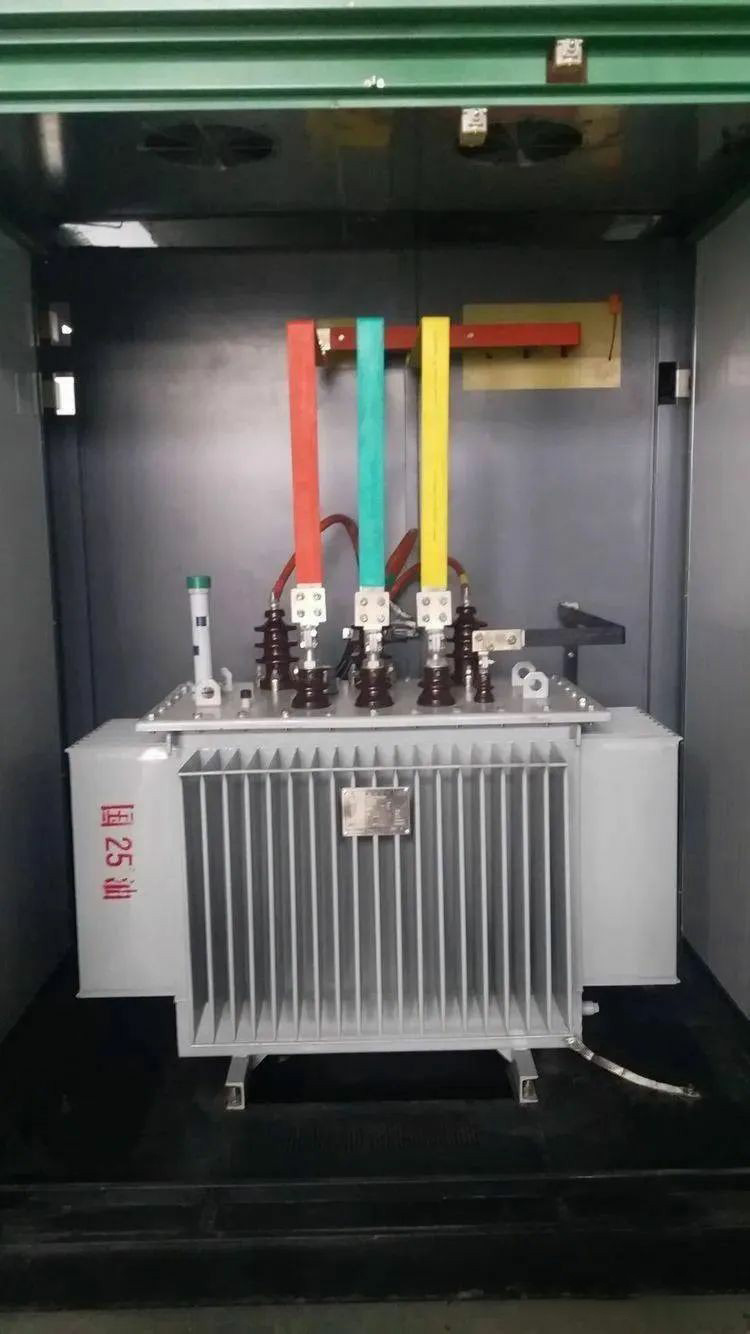

I've sorted this out and categorized it by use, with the following pictures:

(1) Power transformer Power transformer is used for step-up or step-down in the power system for power transmission, distribution and electricity consumption in factories and mines, and is the most common and commonly used transformer. Power transformers can be divided into the following types. (1) Step-up transformer Transmits the low voltage of the power plant to a remote power consumption area after it is raised.

(2) Step-down transformer lowers the high voltage delivered to meet the needs of each power grid.

(3) Distribution transformers are installed in various distribution network systems for industrial and agricultural production.

(4) Liaison transformer for the connection of the two substation systems.

(5) The transformer used in the factory or used is used for the transformer used by the generator or substation, and can also refer to the special transformer for factories and mining enterprises.

(2) Instrument transformer Instrument transformer is used for measuring instruments and relay protection devices. Instrument transformers can be divided into: (1) voltage transformers; (2) Current transformer.

(3) Special purpose transformers Special purpose transformers can be divided into the following types. (1) Electric furnace transformer for smelting. (2) Rectifier transformer for power electrolysis and chemical use.

(3) Test transformer The test transformer has power frequency test transformer, voltage regulator, etc., which are used when testing electrical equipment, and the power frequency test transformer can increase the voltage to test high-voltage electrical equipment. The voltage regulator can adjust the voltage for use during testing.

(4) Electric welding transformer (also known as arc welding transformer) is used for welding.

Second, the specifications and models

of transformers, the specifications and meanings of transformers, there are many specifications and models of transformers, and the meanings of different types of specifications are also different.

Common: Dry-type transformer

"SCB10-1000KVA/10KV/0.4KV" dry-type transformer means that

the meaning of S means that this transformer is a three-phase transformer, and if S is replaced by D, it means that this transformer is single-phase.

C means (dry-type transformer) The winding is a resin cast forming solid.

B means foil winding, if it is R, it is represented as winding winding, if it is L, it is represented as aluminum winding, and if it is Z, it is represented as on-load voltage regulation (copper is not marked).

The representation of 10 is the design serial number, also known as the technical serial number.

1000KVA indicates the rated capacity of this transformer (1000 kVA).

10KV means primary rated voltage, and 0.4KV means secondary rated voltage.

The common "power transformer" specification model indicates the meaning

of the power transformer's model: it is usually composed of symbols that indicate the number of phases, cooling methods, voltage regulation methods, winding cores and other materials, as well as transformer capacity, rated voltage, and winding connection methods.

For example: "SFSZ9-31500/110" transformer model meaning

S: three-phase, F: air-cooled, S: three-winding, Z: on-load voltage regulation, 9: design serial number 9 type.

31500: rated capacity of 31500kVA

110: Specifications and models of box-type transformers with rated voltage of 110kV

on the primary side: box-type transformers (usually referred to as "box-type transformers") are designed in a box-type shell in a centralized manner, with small size, light weight, low noise, low loss and high reliability, and are widely used in residential quarters, commercial centers, light stations, airports, factories and mines, and enterprises, hospitals, schools and other places.

Box-type substations are generally divided into 315, 400, 500, 630, 800, 1000, 1250, 1600, 2000 according to the capacity size (KVA).

3. Specifications and models of transformers and explanation of transformer classification standards and commonly used specifications and models

Specifications are divided into 36 volts, 110 volts, 0.4 thousand volts, 10 thousand volts, 22 thousand volts, 6 thousand volts, 35 thousand volts, 110 thousand volts, 220 thousand volts, 350 thousand volts, 200 thousand volts, 500 thousand volts, 250 thousand volts, 600 thousand volts

According to the capacity, the rated capacity of China's current transformer is in accordance with the R10 priority coefficient, that is, calculated according to the multiple of 10 to the 10th power, 50KVA, 80KVA, There are too many models of transformers such as

100KVA, and the models of transformers are composed of: the number of transformer windings + the number of phases + cooling method + whether to force oil circulation + on-load or no-load voltage regulation + design serial number + "-" + capacity + high-voltage side rated voltage.

For example, SFPZ9-120000/110

refers to the three-phase (double-winding transformer omits the number of windings, if it is three-winding, there is an S in front) double-winding forced oil circulation air-cooled on-load voltage regulation, the design serial number is 9, the capacity is 120000KVA, and the rated voltage on the high-voltage side is 110KV transformer.

The capacity of the transformer according to the national standard is: 30KVA, 50KVA, 63KVA, 80KVA, 100KVA, 125KVA, 160KVA, 200KVA, 250KVA, 315KVA, 400KVA, 500KVA, 630KVA, 800KVA, 1000KVA, 1250KVA, 1600KVA, 2000KVA,

The classification

of transformers is classified by cooling method: dry-type (self-cooling) transformers, oil-immersed (self-cooling) transformers, fluoride (evaporative cooling) transformers.

Classified according to moisture-proof methods: open transformers, potted transformers, sealed transformers.

Classified according to the structure of iron core or coil: core transformer (insert core, C-core, ferrite core), shell transformer (insert core, C-core, ferrite core), ring transformer, metal foil transformer.

Classified by the number of power phases: single-phase transformer, three-phase transformer, multi-phase transformer.

Classified by use: power transformer, voltage regulating transformer, audio transformer, intermediate frequency transformer, high-frequency transformer, pulse transformer.

Second, the characteristic parameters

of the power transformer 1, the working frequency

transformer core loss and frequency have a great relationship, so it should be designed and used according to the use frequency, this frequency is called the working frequency.

2. The rated power

can work for a long time under the specified frequency and voltage, and the output power does not exceed the specified temperature rise.

3. The rated voltage

refers to the voltage allowed to be applied on the coil of the transformer, which shall not be greater than the specified value when working.

4. The voltage ratio

refers to the ratio of the primary voltage and the secondary voltage of the transformer, and there is a difference between the no-load voltage ratio and the load voltage ratio.

5. When the secondary open circuit of the no-load current

transformer, there is still a certain amount of current in the primary, and this part of the current is called no-load current. The no-load current consists of a magnetizing current (which generates magnetic flux) and an iron loss current (which is caused by core loss). For a 50Hz power transformer, the no-load current is essentially equal to the magnetizing current.

6. No-load loss

refers to the power loss measured at the primary level when the transformer is secondary open. The main loss is the core loss, followed by the loss of the no-load current on the copper resistance of the primary coil (copper loss), which is very small.

7. Efficiency

refers to the percentage of the ratio of secondary power P2 to primary power P1. In general, the higher the power rating of the transformer, the higher the efficiency.

8. The insulation resistance

indicates the insulation performance between the coils of the transformer and between the coils and the core. The level of insulation resistance is related to the properties of the insulating materials used, the temperature and the degree of moisture.

Key words:

Aceite-transformador de poder lmmersado

Recommended

Understanding the Role of the Main Transformer in Substations