Transformer Moisture Absorber Silicone Replacement

1. Introduction to transformers

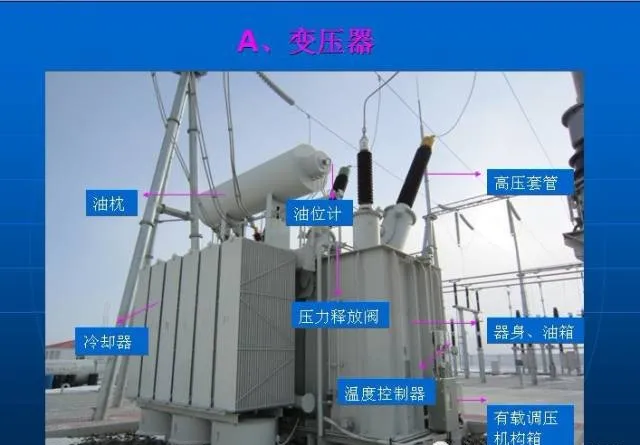

The basic structure of the transformer is composed of the body, oil tank, cooling device, protection device, outlet device and transformer oil. The body includes an iron core, winding, insulation, lead wire and tap changer; The fuel tank comprises the fuel tank body and accessories; The protection device includes oil pillow, oil gauge, safety airway, respirator, temperature measuring element, oil purifier relay, etc.; The outlet device includes high, medium and low voltage porcelain casing, etc.

The oil pillow is installed in the upper part of the transformer oil tank, and is connected with the transformer oil tank through the pipeline, and its functions are: to accommodate the transformer oil that expands and increases due to the increase of transformer temperature; Limit the contact surface between oil and air to reduce the degree of moisture and oxidation of oil; Lubrication through it during operation prevents air bubbles from entering the transformer. Oil pillow is generally divided into two forms: capsule type oil pillow and diaphragm type oil pillow, its function is the same, the main function of the capsule or diaphragm is to isolate oil and air. The gas in the oil pillow capsule is exchanged with the outside world through the respirator.

2. Structure and function

of respirators (1) Structure and function of respirators

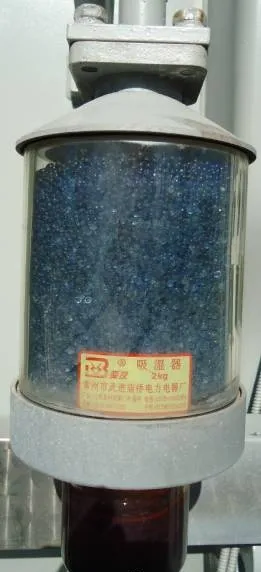

The respirator, also known as the dehydrating breather, is filled with adsorbent, and the adsorbent often uses color-changing silica gel, which is used to absorb moisture in the air and reduce the moisture and oxidation of transformer oil. The gas relay is installed on the connecting pipe between the tank and the oil pillow, so that the gas generated in the fuel tank must pass through the gas relay before it can flow to the oil pillow.

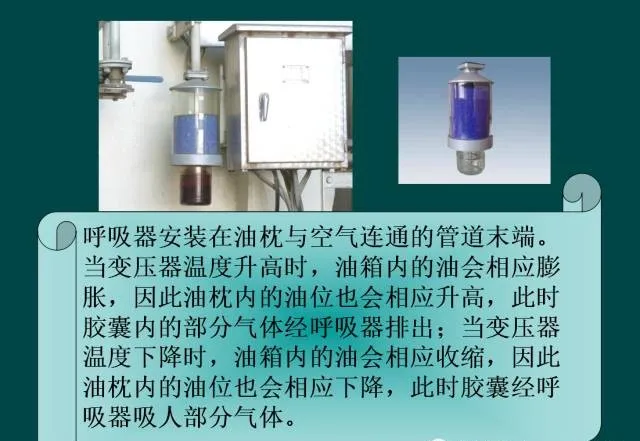

The respirator (pictured) is installed at the end of the pipe where the oil pillow communicates with the air. The common transformer respirator is mainly composed of an iron tube, a glass container and an oil cup, the glass container is filled with desiccant (such as silica gel), and the oil cup is filled with a certain amount of insulating oil. When the air in the transformer oil conservator expands or shrinks with the volume of the transformer oil, the air discharged or inhaled passes through the respirator, and the desiccant in the respirator absorbs the moisture in the air, which dries and filters the air, so as to keep the insulating oil in the transformer oil tank clean. 3. Daily management and maintenance

of respirator Respirator is the main organ of respiration in the transformer oil tank, and the daily maintenance of respirator is related to the cleaning of the internal insulating oil of the main transformer. Long-term neglect of management of respirators will cause the internal insulating oil of the transformer to be damp, the insulation strength will decrease, and in severe cases, electrical failures will occur. As an operation manager, it is necessary to strengthen the daily inspection management of the respirator, and as a maintenance personnel, it is necessary to formulate a maintenance strategy in a timely manner according to the status of the respirator and do a good job in various maintenance work. The following requirements should be paid attention to during the daily inspection of transformer respirators: First, the amount of silica gel should account for two-thirds of the volume of the respirator, and when the silica gel discoloration part accounts for more than one-third of the whole, it should be replaced in time, according to the current state grid company state maintenance regulations, when the silica gel discoloration is two-thirds, the transformer equipment is in an abnormal state. As shown in Fig

Second, the height of the insulating oil in the oil cup should be higher than the lowest end of the oil pipe, so as to play the role of sealing and dust removal. The insulating oil of the oil cup shall not exceed the highest scale indicated by the oil label, otherwise it will cause the breathing hole plug to be blocked, and the respirator will not be able to exhale normally.

Third, the sealing of the respirator needs to be good, the discoloration of the silicone should start from the bottom, if the upper color changes color, it means that the respirator is not tightly sealed, in order to ensure the normal operation of the respirator, the respirator sealing needs to be adjusted in time.

Fourth, when the oil level indication is abnormal or there is no breathing phenomenon in the main transformer respirator, the tracking analysis should be strengthened to determine whether the breathing hole of the respirator is blocked through analysis, resulting in the formation of negative pressure inside the main transformer. When the oil level is too high and the respirator spills and causes silica gel pollution, the oil tracking of the main transformer body should be strengthened in time and the silica gel should be replaced in time.

3. Respirator silicone replacement (1) Preparation before replacement: prepare corresponding tools and materials

Handle the second type of uninterrupted work ticket, apply to the dispatcher to withdraw from the hard pressing plate of "local heavy gas starting tripping" and "loaded gas starting tripping", and change the main transformer gas protection to signal operation mode. If you only replace the silicone (large tank) next to the ladder, you will return the weight gas of the body, and only replace the loaded silicone (small tank) next to the oil temperature gauge, and you will only return the load gas (2) The correct steps for silica gel replacement: 1. Remove the respirator first, that is, loosen the four screws at the connection between the respirator and the oil pillow breathing tube, and remove the respirator (note that the respirator should be supported from the bottom to avoid it falling and breaking). Wrap the breathing tube in a fresh, dry towel to prevent air and impurities from entering the pillow directly.

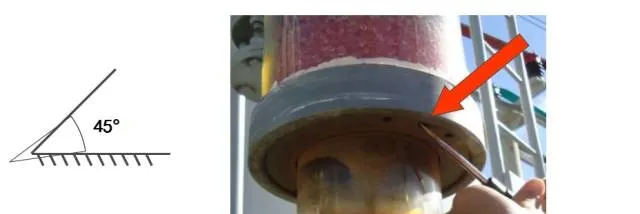

2. Remove the respirator oil tank and place the respirator obliquely at 45°, loosen the bottom rotating plate of the respirator (with 6 small holes) in the counterclockwise direction with a "one" screw pen, rotate and remove the oil tank, and then loosen the two small nuts to remove the small glass cylinder (clean the oil tank with oil).

4. Remove the top cover of the silicone tank and unscrew it and remove the long screw, place the respirator vertically, lift the top cover up to open the silicone tank, and replace it with a new silicone. (If it has been sealed with glass glue, use a knife to scrape the sealing part of the glass glue first, remember not to use brute force)

3. Installation of respirators and inspection 1. Installation method: Contrary to the above removal steps (the oil level in the large glass cylinder is 1cm higher than the lowest oil level, and the small glass cylinder at the bottom is immersed in the oil of the large glass cylinder)

2. Inspection: (1) Check whether the respirator sealant is tight; (The upper and lower connecting parts of the transparent tank should be sealed with glass glue) (2) Check whether the oil drain valve of the main transformer body is closed tightly and there is no oil leakage; (3) Observe that the small window of the light gas relay should be filled with oil; (4) After the main transformer body runs for one hour, check that the light gas relay should be separated without gas Finally, the inspection results are reported to the dispatcher, and the hard pressing plate of "local heavy gas starting tripping" and "loaded gas starting tripping" is put into the dispatching order to restore the normal operation of the main transformer gas protection. (If gas is found, it should be truthfully reported and wait for the maintenance personnel to deal with it)

Within 48 hours after recovery, the following places should be paid close attention to:

1. Whether there is gas in the small window of the light gas relay; 2. Check the color of the newly replaced silica gel, and whether there is oil entering the small tank at the bottom; 3. Clean up the residual oil outside the replaced dehydrating absorber with oil blotting paper, and replace the pebbles under the dehydrating breather and grease drain nozzle to check whether there is oil leakage;

4. Precautions for respirator silicone replacement Silicone replacement should be carried out in good weather and moderate air hours. And take care to keep a safe distance from the live part. Immediately after removing the respirator, the breathing tube tip should be wrapped with clean plastic paper to prevent moisture from entering.

When replacing, the insulating oil in the oil cup should be replaced, and a sufficient amount of qualified new oil should be added to ensure that the insulating oil can effectively filter dust.

When replacing the silica gel, the main transformer body (pressure regulation) should be withdrawn from the heavy gas protection, if the negative pressure is formed inside the main transformer, replacing the silica gel will cause gas malfunction.

If the silicone gets into the eye, rinse with plenty of water and seek treatment from a doctor as soon as possible. Blue silica gel is toxic due to the content of a small amount of cobalt oxide, so avoid contact with food and inhalation in the mouth, if poisoning occurs, you should immediately seek medical treatment.

The replaced silica gel should be properly stored to prevent soil and air pollution. When the stock is large, it can be heated and dried with a large spoon, and it can be continued to be used to reduce operating costs. The temperature of desorption regeneration should not exceed 120 °C, otherwise it will lose its chromogenic effect due to the gradual oxidation of the chromogenic agent.

5. Case analysis of respirator management failureCase 1: During the periodic preventive test of the No. 1 main transformer of a substation, it was found that the test data of the transformer's insulation resistance and leakage current were unqualified

The simplified oil test found that the compressive strength of the insulating oil was 1.8kV, and there were potential safety hazards in the insulating oil equipment. Through inspection, it was found that the sealing of the equipment body was good, and there was no leakage and water ingress. After opening the gas relay, it was found that there was water accumulation (about 10g) and corrosion phenomenon inside, there was water accumulation at the bottom of the oil tank of the pressure regulator switch, about 100g, and the silica gel in the pressure regulator switch and the respirator of the oil conservator of the body was seriously discolored. Through the analysis, it is concluded that the reduction of transformer insulation is mainly caused by the abnormality of the respirator. After the respirator silicone is severely discolored, the moisture in the air directly enters the oil storage tank, and with the change of temperature, condensation forms in the tank wall. Condensate water is carried out in the oil tank, so that the water content of transformer oil increases, the insulating oil deteriorates, and the dielectric strength decreases. After the insulating oil is dried and filtered, and the respirator inspection and management are strengthened, the equipment runs stably.

Case 2: In the process of discoloration and elimination of silicone in the main oil pillow respirator of a substation, the non-electric protection action of the transformer itself caused the circuit breaker on the high and low voltage side of the main transformer to trip

The transformer's high-voltage electrical test, oil inspection test, and ontology inspection were not found to be abnormal. Through the maintenance process, it was found that when the maintenance personnel replaced the silica gel, they did not withdraw the local heavy gas protection in time. The breathing plug of the respirator of the oil conservator is contaminated with dust and cannot breathe, and there is negative pressure inside the transformer. When the maintenance personnel remove the respirator, a large amount of gas enters the transformer, causing a large amount of oil flow inside the transformer gas relay, causing gas malfunction.

Key words:

Aceite-transformador de poder lmmersado

Recommended

Understanding the Role of the Main Transformer in Substations